We can laminate to sheets with precision.

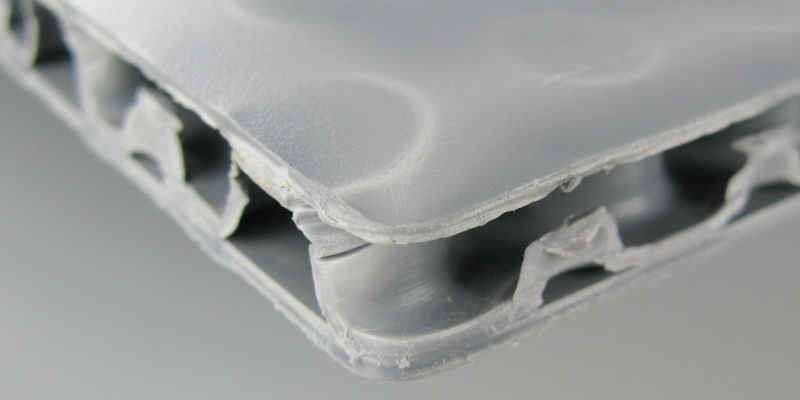

Laminating to sheets involves sealing two or more sheets of material together to create a single composite sheet. When we laminate to sheets, we apply a layer of adhesive to the substrate to allow the film or fabric to bond the sheets together. This provides the sheets with increased durability, strength, and protection.

When laminating to sheets, the first step in the process involves picking a laminating film or material that best suits the requirements of the packaging. Factors such as barrier properties, durability, and needs for product visibility must be considered.

As mentioned, laminating to sheets delivers enhanced durability and protection against moisture and physical damage. But it can also help maintain the quality and integrity of the packaged goods. We often recommend laminating to sheets for products that require an extended shelf life or face challenging environmental conditions either during transportation or storage.

At L-S Industries, we provide quality laminates to create high-quality reusable packaging. We can laminate many types of materials, including Evolon, Tyvek, brushed polyester, closed-cell foam, and spunbond to create non-scratch surfaces for packaging. We can laminate just one side of the sheet, both sides of the sheet, or even roll over the edges to provide a smooth top to partition sets.

Producing a quality product is always our driving force with laminating to sheets and laminating other products for packaging purposes. For more information about our laminating process or to place an order, reach out to us today.