Plastic Corrugated Rolls

Plastic corrugated is primarily known for its use in the sign industry. It is an extruded material and can be run in rolls as well for a variety of applications.

The rolls generally do not vary in thickness but in product weight. It is measured by how many pounds of plastic are extruded per manufactured square foot (1,000sqft). L-S Industries offers multiple types of plastic corrugated rolls, as well as the ability to laminate foams, fabrics, and printed films. While these plastic rolls are perfect for protecting products that are round, there are many more applications in which thick plastic rolls can be used.

Types

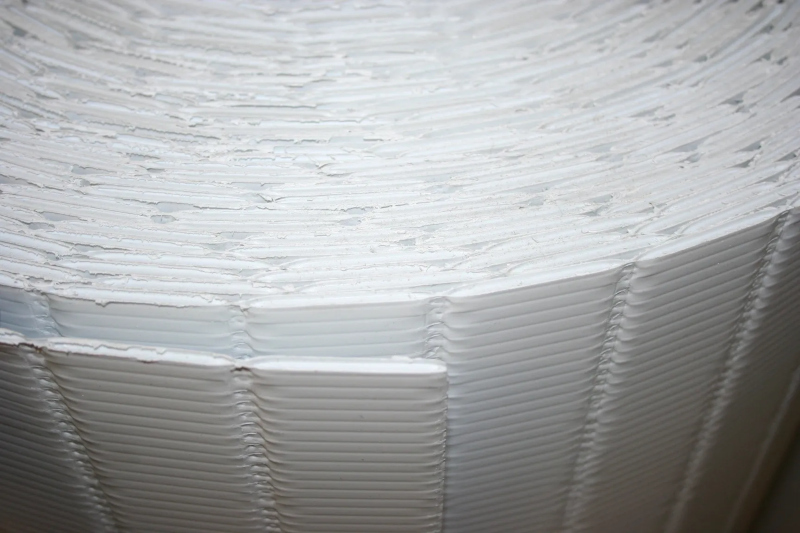

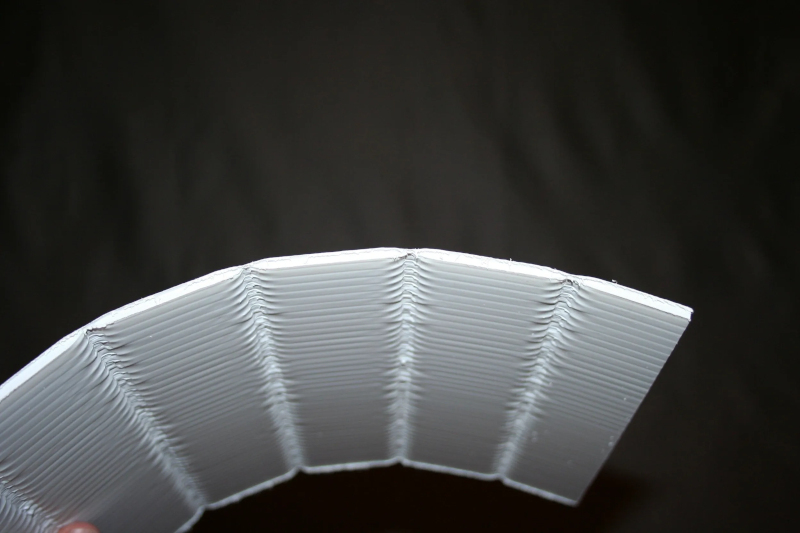

HEAT-SCORED

Polypropylene-based, heat-scores every 2 inches allow this material to roll up. PP is a harder plastic.

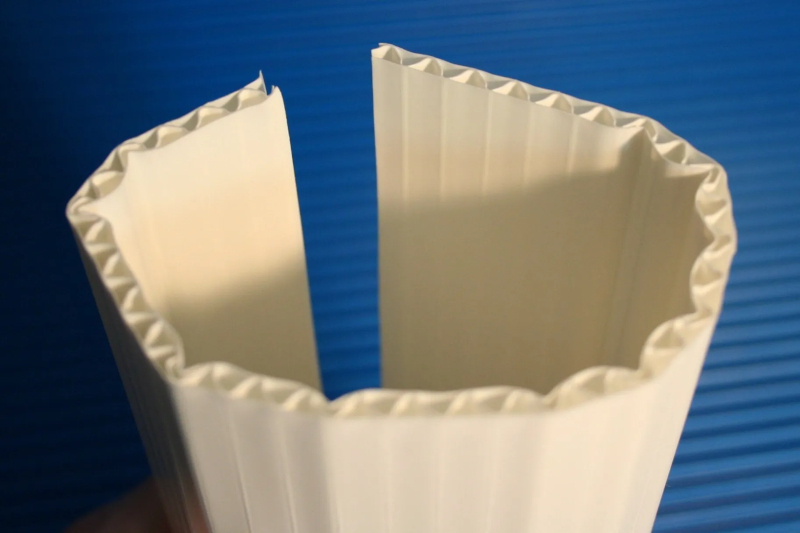

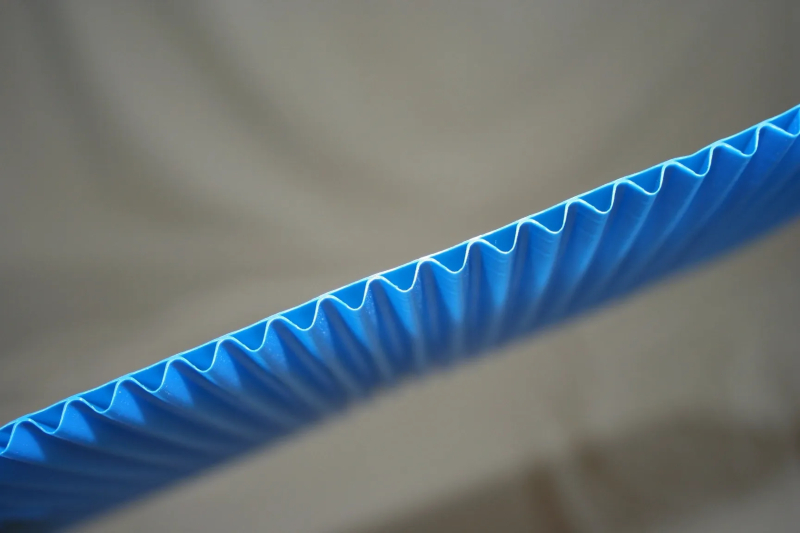

DOUBLE-FACE

SINGLE-FACE

Applications

PROTECTIVE REEL WRAPS

Products, like wire & cable, shipped and stored on reels require protection from impact as well as the elements.

PROTECTIVE EXPORT WRAPS

Plastic rolls make an excellent protective wrap for round products like aluminim & steel coils.

PROTECTIVE PIPE WRAPS

Long downhole pipes and sandscreens can be protected with plastic corrugated rolls with foam backing.

PROTECTIVE CASE WRAPS

Plastic rolls apply easily to large HVAC units, appliances, and other sensitive surfaces to protect them during shipment.

TREE WRAPS

Single-face makes an excellent tree wrap to protect young trees from weather, chemical sprays, and rodents.

OTHER APPLICATIONS

The flexibility of single-face allows you to create a pin or backdrop for a variety of different applications.