CAPABILITIES

We offer custom conversion and material fabrication solutions meaning that we have the capability to cut, laminate, and seal plastics and other materials. The materials and products you’ll see on this site are only a sampling of the materials we can fabricate. We’re constantly looking for new materials and applications.

We offer custom conversion and material fabrication solutions meaning that we have the capability to cut, laminate, and seal plastics and other materials. The materials and products you’ll see on this site are only a sampling of the materials we can fabricate. We’re constantly looking for new materials and applications.

Our team can help you select the right material for your specific application.

Some of the industries we’ve worked with include wire and cable, aluminum and steel, horticulture, document handling, warehousing, automotive, real estate, material handling, and much more.

CUTTING

L-S Industries, Inc. specializes in cutting rolled materials to size, both width and length. We can also cut sheets to your specifications. Rectangle, square, circle, or donut-shape are our specialties but we can also have materials die-cut to create a custom product for your application.

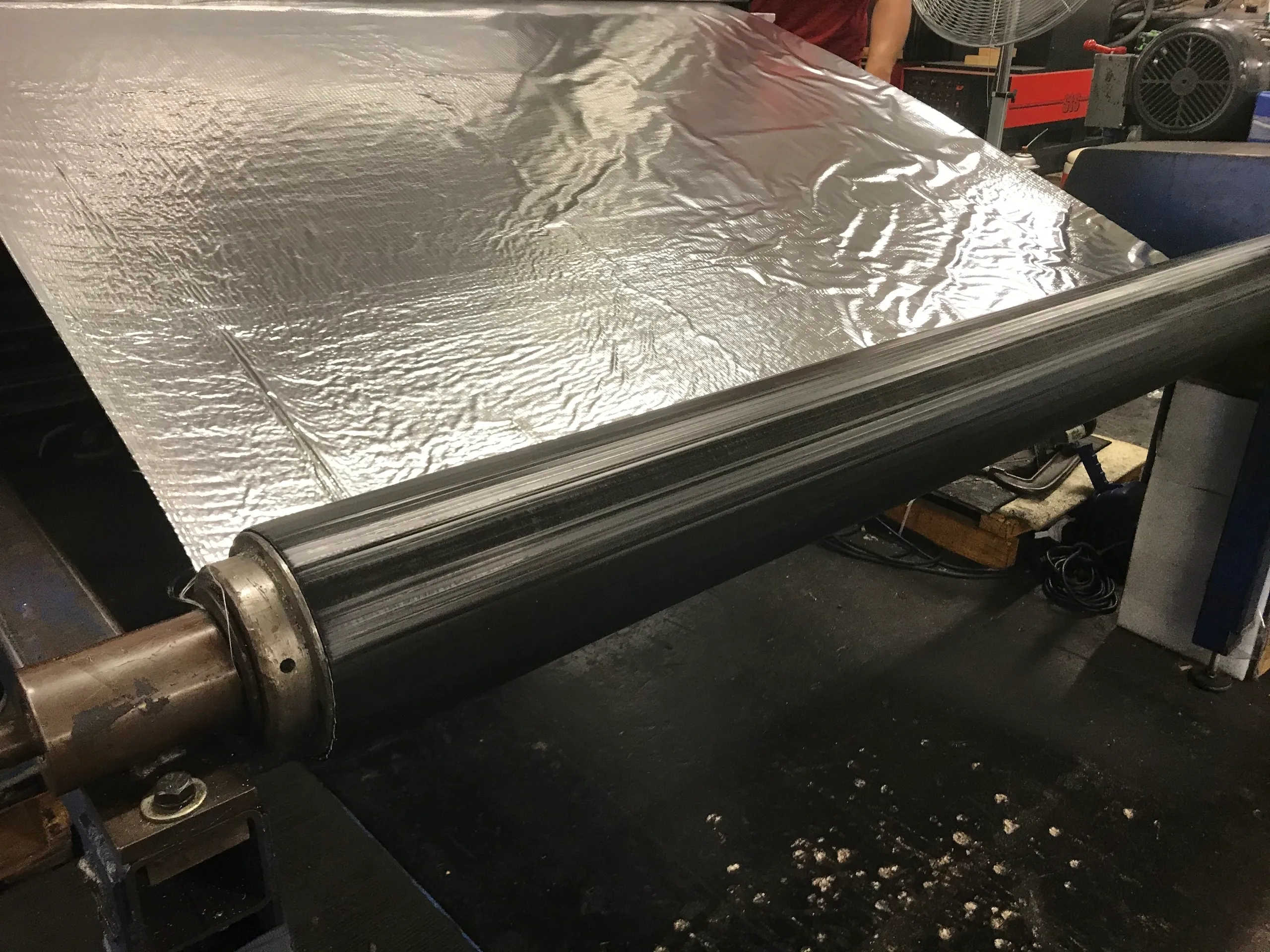

LAMINATING

L-S Industries, Inc. uses hot-melt laminators to adhere two different materials together. We can laminate just about any material but specialize in various foams and fabrics to plastic corrugated. We can laminate roll to roll and roll to sheet, depending on the material.

SEALING

We have sonic-welders and heat-sealers to adhere plastic materials together. Sonic-welding is primarily used to make totes and boxes out of plastic corrugated. We also have welding equipment for aluminum and steel.